PRINTED PLASTICS, WE ARE COMMITTED TO QUALITYSAFETY

ABOUT US

Established in 1957, Plestin was initially created to manufacture plastic components intended to replace those existing in automotive batteries, made out of thermosetting resins (bakelite, ebonite) or cork.

Company

O parque fabril da Plestin possui 3.800 m2 de área construída em um terreno de 6.300 m2.

Inventory

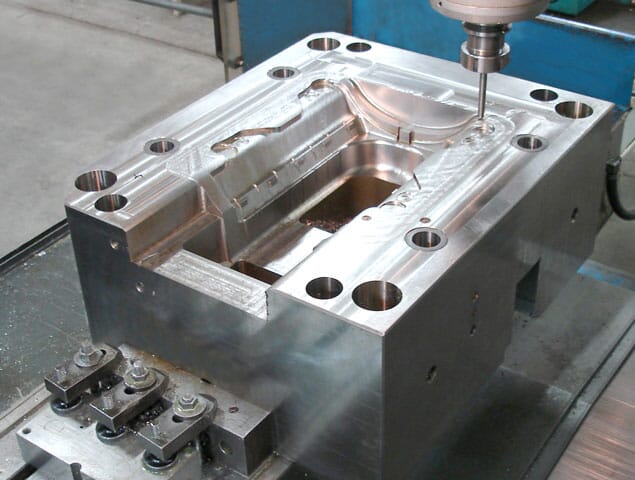

The project department assists our customers in designing new products, doing everything from design to 3D model finalization. With our own tooling department, our molds are made according to the highest quality standards.

CNC machining equipment allows for mold construction within deadlines and perfectly aligned with our customers’ needs.

Cutting-edge injection molding machines allows us to meet our customers’ most varied needs.

Our industrial plant is equipped with modern injection molding machines, ranging from 80 tons to 470 tons, capable of injection molding up to 2.1 kg in Polystyrene.

Production

Highly specialized in technical parts, Plestin develops and produces an extensive range of products in the automotive and industrial areas.

Expanding to new markets, in 2006 Plestin rolled out a cutting-edge, complete range of dispensers and products for professional hygiene and cleaning.

This range ranges from liquid soap to the most diverse types of paper towels, in addition to products for liquid soap and liquid alcohol bottling.

In 2018, this range was upgraded with the Century models.

Today, Plestin stands out as one of the largest dispenser manufacturers in Brazil and South America.

Quality Policy

“Production of dispensers for hygiene and cleaning products and fractionation of cosmetics to be marketed according to market requirements and expectations.”

“Continuously improve manufacturing processes and partnerships with our Customers, Suppliers, and Community.”

“To satisfy our Customers through a policy conceived to ensure a fair price, ethical conduct, and to preserve the environmental at the same time.”

Quality

Our quality assurance system is ISO 9001-2015- certified, allowing us to work with very low rejection rates, without compromising lead times.

To make high-tech injection molds, at Plestin we have the ideal solution to produce injection-molded technical parts in a wide range of thermoplastics.

Molds

Plestin owns cutting-edge tools for mold construction and maintenance, fitted with ultramodern CNC machining equipment, a design department with a CAD/CAM system, 3D modeling, and design techniques that have been tested over the years in our injection molding department.

You will not only be buying a mold, but also be able to injection mold your part with the person who built it, and this will undoubtedly guarantee your product will perform as you want it to.

Miscellaneous

Plestin's industrial and project structure affords our customers an excellent cost-benefit ratio, allowing the production of injection-molded technical parts of up to 2.1 kg with the quality standard required for each application.

Our ISO 9001-certified quality assurance system allows us to work with very low rejection rates, without compromising lead times.